Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

Is Silicone a Rubber or Plastic?

Silicone is a versatile material found in numerous products we use daily, from kitchenware to medical devices. However, there's often confusion about whether silicone is classified as a rubber or a plastic. This article will delve into the nature of silicone, its properties, and its applications to clarify this common question.

What is Silicone?

Silicone is a synthetic polymer composed of silicon, oxygen, carbon, and hydrogen. It is known for its unique properties, which include flexibility, thermal stability, and chemical resistance. These properties make silicone highly adaptable and useful in various applications.

Silicone polymers are constructed from a backbone of alternating silicon and oxygen atoms, with organic groups attached to the silicon. This distinctive structure contributes to its remarkable stability and resistance to extreme environments.

Silicone as a Rubber

Explanation of Silicone Rubber

Silicone rubber is a type of elastomer, meaning it exhibits elasticity similar to natural rubber. Key properties of silicone rubber include:

- Elasticity: It can stretch and return to its original shape without permanent deformation, which is crucial for applications like seals and gaskets that require flexibility and resilience.

- Heat Resistance: It remains stable and maintains its properties over a wide temperature range (-60°C to 300°C), making it suitable for environments with fluctuating temperatures.

- Chemical Stability: Resistant to many chemicals, including acids and bases, which makes it suitable for various industrial applications. This resistance is vital for use in harsh chemical environments and for long-term durability.

Common Applications of Silicone Rubber

- Seals and Gaskets: Used in automotive, aerospace, and industrial applications for creating leak-proof seals. For instance, in the automotive industry, silicone rubber gaskets ensure that engines and other components remain leak-free under high pressure and temperature conditions.

- Medical Devices: Utilized in catheters, implants, and other biocompatible products due to its non-toxic nature. Its flexibility and biocompatibility make it ideal for long-term medical implants that need to adapt to the human body without causing adverse reactions.

- Consumer Products: Found in baby products, kitchenware, and personal care items like toothbrushes and cosmetics. Silicone’s non-toxic and hypoallergenic properties make it safe for use in items that come into direct contact with skin and food.

Silicone as a Plastic

Explanation of Silicone in Plastic-like Applications

While silicone exhibits rubber-like properties, it can also function similarly to plastic in certain applications:

- Flexibility: It can be molded into various shapes while maintaining durability. This flexibility allows for the creation of complex and intricate designs that would be difficult with more rigid materials.

- Durability: Silicone is resistant to UV radiation and environmental degradation, ensuring long-term performance even in outdoor applications.

- Moldability: It can be easily molded into intricate shapes, making it ideal for detailed applications such as electronic components and medical devices.

Common Applications Where Silicone Acts Like Plastic

- Kitchenware: Silicone baking mats, spatulas, and molds are popular due to their non-stick and heat-resistant properties. These items can withstand high oven temperatures without melting or releasing harmful chemicals, ensuring food safety.

- Electronics: Used in keypads, waterproof seals, and protective coatings for electronic components. Silicone’s insulating properties protect sensitive electronic components from moisture and contaminants, prolonging their lifespan.

- Coatings: Applied in construction for protective and waterproof coatings. Silicone coatings provide a durable, weather-resistant barrier that protects buildings and structures from the elements.

Differences Between Silicone Rubber and Plastic

Structural Differences

- Silicone Rubber: Elastomeric structure with flexibility and elasticity. The siloxane backbone with organic side groups allows for stretchability and resilience.

- Plastic: Rigid polymer chains that provide strength and rigidity. Traditional plastics like polyethylene and polypropylene have a more straightforward carbon-based structure that lends to rigidity.

Property Differences

- Silicone Rubber: Known for its elasticity, flexibility, and heat resistance. These properties make it suitable for dynamic applications that require materials to move and adapt without losing their integrity.

- Plastic: Typically rigid, durable, and can be transparent or opaque. Plastics are often chosen for applications requiring strength and a fixed shape, such as containers and structural components.

Functional Differences

- Silicone Rubber: Suitable for applications requiring flexibility and durability under extreme conditions. Ideal for products that experience repeated motion and stress, such as medical tubing and automotive parts.

- Plastic: Ideal for rigid structures and products requiring specific shapes and strengths. Used extensively in packaging, construction, and consumer goods where a stable and predictable form is essential.

FAQs for Silicone

Is silicone a rubber?

Yes, silicone is often used as a rubber due to its elastic properties and resistance to extreme conditions. It functions effectively as a rubber in applications that benefit from its flexibility and resilience.

Is silicone a type of plastic?

Silicone can function similarly to plastic in certain applications, especially where flexibility and moldability are required. While it shares some characteristics with plastics, it also retains the unique properties of rubber.

What is silicone used for?

Silicone is used in medical devices, kitchenware, electronics, construction, and consumer products. Its versatility makes it a material of choice across various industries.

Is silicone safe for cooking and baking?

Yes, silicone is safe for cooking and baking. It is non-toxic and heat-resistant, often used for its non-stick properties. Silicone kitchen products are FDA approved and safe for food contact, ensuring they do not leach harmful substances.

How does silicone compare to other materials like latex and plastic?

Silicone is more durable, flexible, and heat-resistant compared to latex and plastic. It is also hypoallergenic and biocompatible, making it suitable for medical and food applications. Unlike latex, silicone does not cause allergic reactions, and it offers greater temperature and chemical resistance than many traditional plastics.

Environmental Impact of Silicone

While silicone is not biodegradable, it can be recycled. Efforts are ongoing to improve the sustainability of silicone production and recycling processes. Additionally, silicone's durability means products last longer, reducing waste over time. Silicone’s long lifespan reduces the need for frequent replacements, contributing to a lower environmental footprint compared to materials that degrade more quickly.

Conclusion

Silicone's unique properties allow it to function both as a rubber and a plastic, depending on the application. Its versatility, durability, and safety make it an essential material in many industries. Understanding whether silicone is a rubber or plastic depends on its use, but it is clear that silicone’s benefits are vast and impactful.

For more detailed information on the applications of silicone, check out this resource on applied silicone.

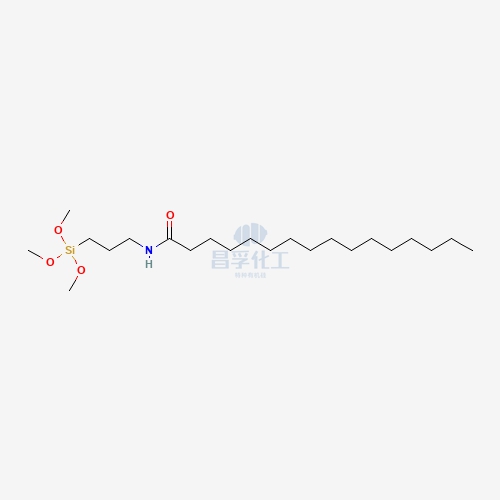

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog