Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

Epoxy Silanes

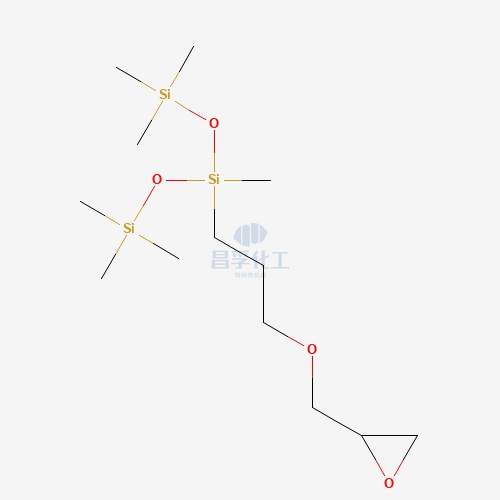

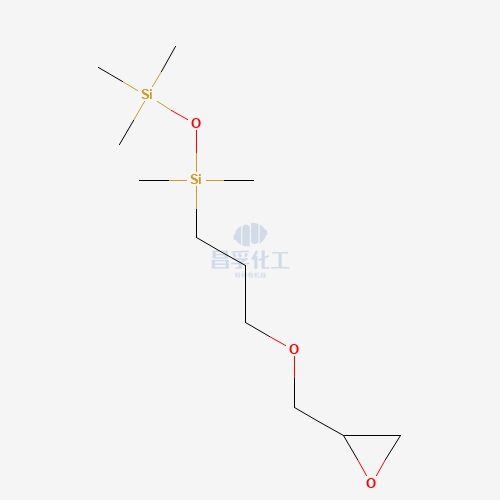

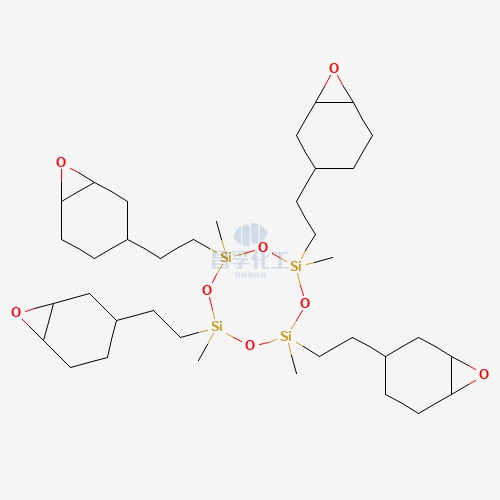

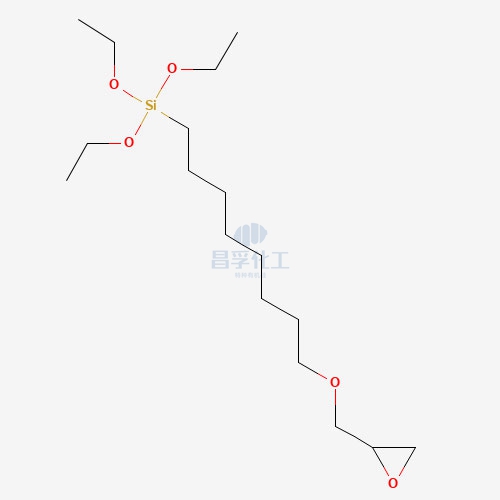

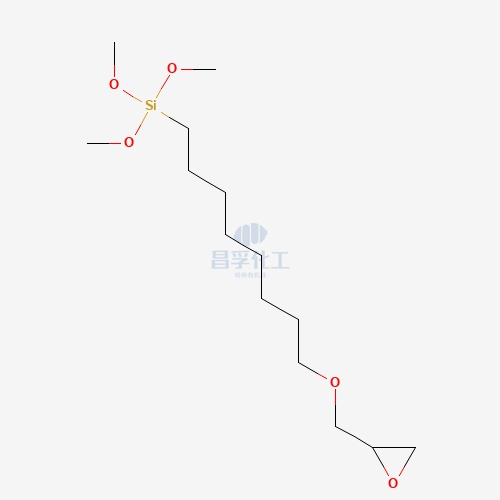

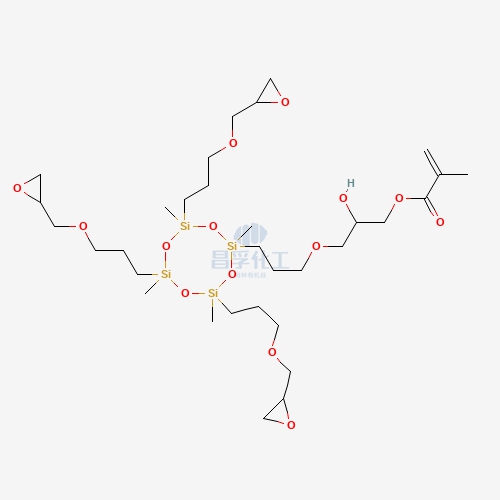

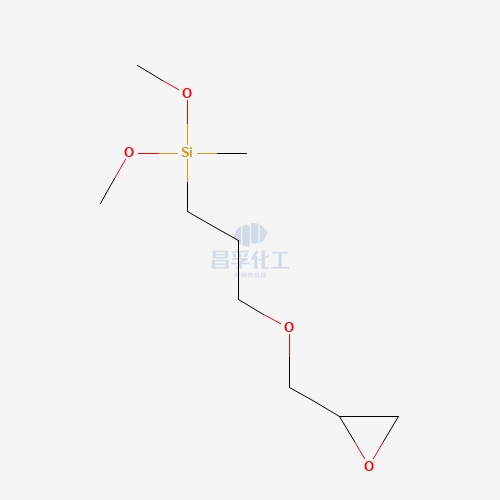

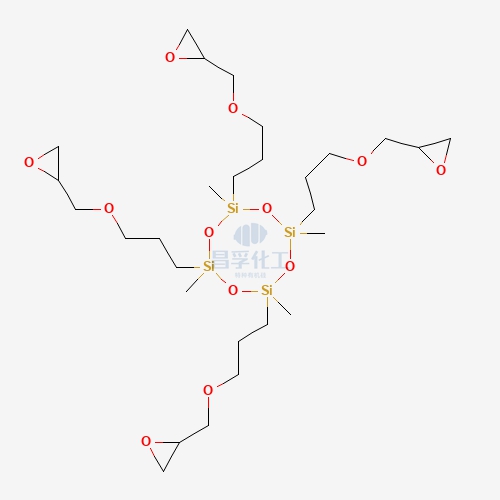

Epoxy silanes are organosilicon compounds containing an epoxy group on one end and a hydrolyzable alkoxy group on the other. This unique structure allows epoxy silanes to have decreased surface tension, high reactivity, and great stability, as well as the ability to chemically react with a wide range of materials to generate superior modification and bonding performance.

Epoxy Silanes

Epoxy silanes are organosilicon compounds containing an epoxy group on one end and a hydrolyzable alkoxy group on the other. This unique structure allows epoxy silanes to have decreased surface tension, high reactivity, and great stability, as well as the ability to chemically react with a wide range of materials to generate superior modification and bonding performance.

Epoxy Silanes For Sale

Epoxy Silanes For Sale

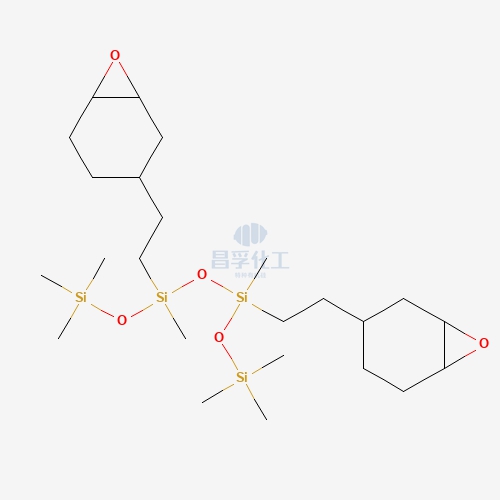

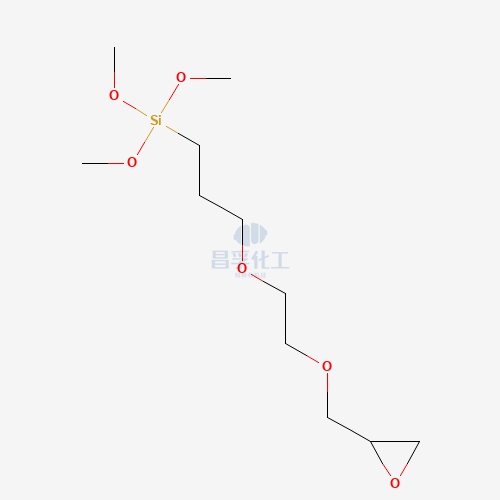

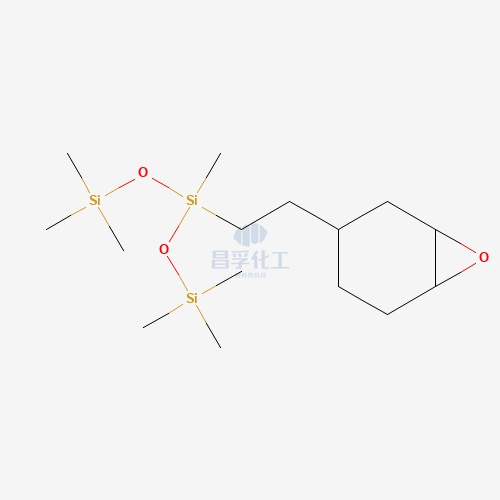

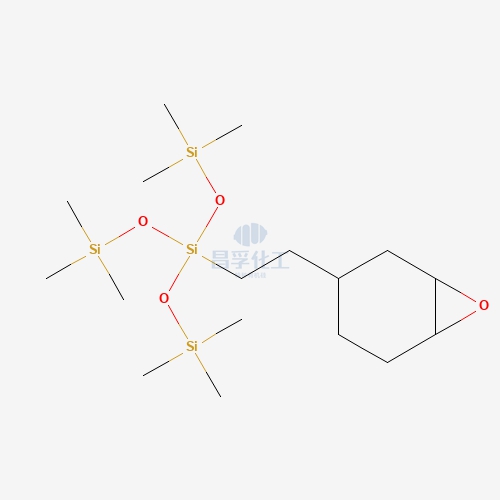

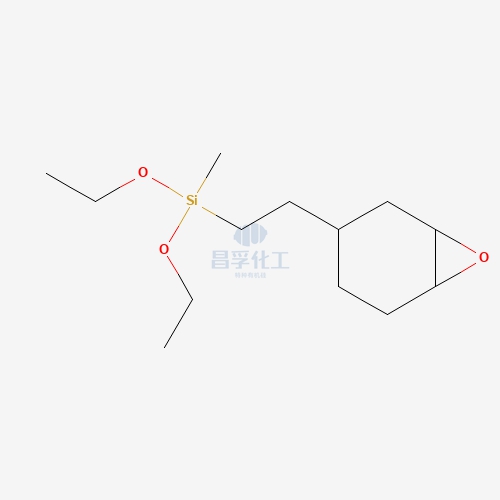

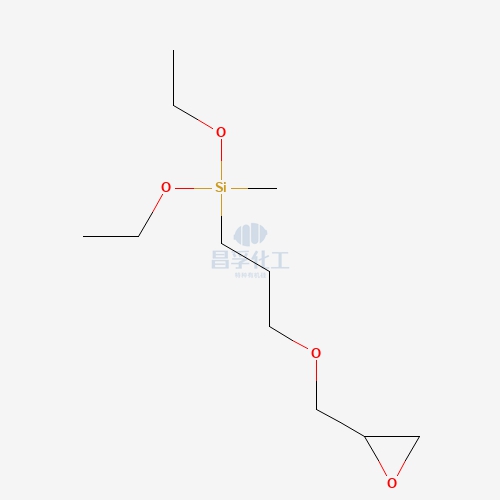

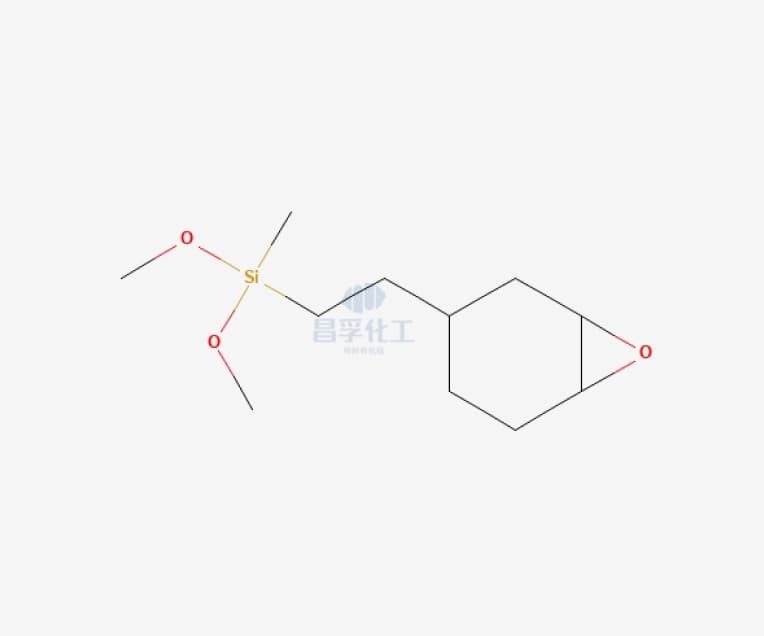

Changfu Chemical offers two types of epoxy silanes: glycidoxy silanes and epoxycyclohexyl silanes. These epoxy silanes are primarily generated using a hydrosilylation reaction process and have been widely employed as silane coupling agents and fabric softening finishers. Because of the tension, the epoxy group has very active chemical characteristics and a strong tendency to open the ring; particularly when catalyzed by acid and strong base, it can quickly open the ring and react with nucleophiles and compounds containing active hydrogen.

Changfu Chemical offers two types of epoxy silanes: glycidoxy silanes and epoxycyclohexyl silanes. These epoxy silanes are primarily generated using a hydrosilylation reaction process and have been widely employed as silane coupling agents and fabric softening finishers. Because of the tension, the epoxy group has very active chemical characteristics and a strong tendency to open the ring; particularly when catalyzed by acid and strong base, it can quickly open the ring and react with nucleophiles and compounds containing active hydrogen.

Uses of Epoxy Silanes

Uses of Epoxy Silanes

1. Adhesives & Sealants

2. Coatings & Inks

3. Fiber treatment

4. Packaging

5. Medical