Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

The Science Behind Silicone Monomers: From Synthesis to Application

Understanding the behavior of monomers and polymers is essential for creating materials with specific characteristics, such as flexibility, strength, or resistance to heat. Silicone monomers play a pivotal role in the production of various silicone-based polymers, materials that are widely utilized in industries ranging from healthcare and automotive to electronics and construction. Understanding the science behind silicone monomers—how they are synthesized, their unique properties, and how they are applied in different fields—provides insight into the versatility and significance of silicones in modern technology and manufacturing. This blog will delve into the chemistry of silicone monomers, their synthesis, and explore their wide-ranging applications, highlighting the ways in which these materials have revolutionized multiple industries.

What Are Silicone Monomers?

At their core, silicone monomers are small molecular units that contain silicon atoms bonded to organic groups, such as methyl or phenyl, with oxygen atoms forming bridges between silicon atoms. These monomers are the building blocks for larger polymer chains known as silicones, which are created through polymerization processes. Silicone monomers are typically low-molecular-weight compounds that contain silicon-oxygen backbones, forming the basis for flexible, heat-resistant, and chemically stable materials.

Unlike traditional organic polymers that are primarily based on carbon-carbon bonds, silicones are based on a silicon-oxygen backbone, which imparts distinctive properties such as resistance to temperature extremes, flexibility, and excellent water-repelling abilities. This unique chemistry makes silicone monomers essential for the creation of silicone polymers, which can be adapted for various industrial uses, from high-temperature seals to medical implants.

The Chemistry of Silicone Monomers

Silicone monomers are organic compounds that feature the fundamental building block known as siloxane (Si-O) bonds, which provide them with a remarkable combination of mechanical and thermal properties. The presence of silicon—being less electronegative than carbon—creates bonds that are more resistant to thermal degradation, oxidative damage, and environmental stress. Silicon is also more resistant to moisture and oxidation compared to other metals, further enhancing the stability and durability of silicone-based materials.

The typical structure of silicone monomers consists of silicon atoms connected by oxygen atoms (Si–O–Si) to form a flexible, highly stable network. Organic groups such as methyl (–CH₃), phenyl (–C₆H₅), or vinyl (–C₂H₃) groups are attached to the silicon atoms, imparting specific properties to the final silicone polymer. These organic substituents influence characteristics such as flexibility, hardness, and compatibility with other materials. Silicone monomers can also contain functional groups like hydroxyl (-OH), vinyl, and amino groups, enabling further modification and crosslinking in the polymerization process.

The Synthesis of Silicone Monomers

The process of synthesizing silicone monomers involves several chemical steps, each of which contributes to the final characteristics of the monomer. The most common method of synthesizing silicone monomers is through the reaction of silanes (Si-H compounds) with various organic functional groups or precursors. Silane-based reactions, especially those involving the hydrolysis of chlorosilanes, form the basis of commercial silicone production.

Step 1: Preparation of Silanes

Silicon-based chemicals, known as silanes, are the precursors to silicone monomers. The simplest silane compound is silicon tetrachloride (SiCl₄), which reacts with organic compounds containing reactive groups to form functionalized silanes. The reaction typically involves the substitution of chlorine atoms on the silane with organic groups, such as alkyl or phenyl groups.

For example, methylchlorosilane (CH₃SiCl₃) can be synthesized by reacting silicon tetrachloride with methyl chloride (CH₃Cl). This silane can then undergo hydrolysis in the presence of water to form silanol groups (Si-OH), which serve as the basis for polymerization.

Step 2: Hydrolysis and Condensation

Once silanes are synthesized, the next step is to hydrolyze them, which involves adding water to the silane compounds to form silanol groups. The reaction of silanes with water yields silanol groups and by-products such as hydrochloric acid.

This silanol group (-SiOH) is crucial because it can undergo condensation reactions to form the siloxane (Si-O) bonds that are the backbone of silicone polymers. The silanol groups condense with each other to form siloxane linkages, releasing water as a by-product.

As the condensation process continues, longer chains of siloxane are created, eventually forming the silicone polymers that can be further cross-linked or modified depending on the desired properties of the final product.

Step 3: Polymerization and Functionalization

Once the basic silicone monomer has been synthesized, it can undergo polymerization to form either linear or cross-linked silicone polymers. In some cases, additional organic groups (such as vinyl or amino groups) are introduced during the polymerization process to modify the properties of the final material.

For example, when silicone monomers containing vinyl groups undergo polymerization in the presence of a free radical initiator, the resulting polymer can form cross-linked networks, which are valuable for applications requiring high thermal stability and flexibility. Functional groups, such as methoxy or hydroxyl, can also be incorporated to create monomers that are reactive under certain conditions, enhancing the monomer’s compatibility with other materials.

Types of Silicone Monomers

Silicone monomers are not a singular, uniform class of compounds; instead, they vary significantly depending on the organic groups attached to the silicon atoms. The most common types of silicone monomers include:

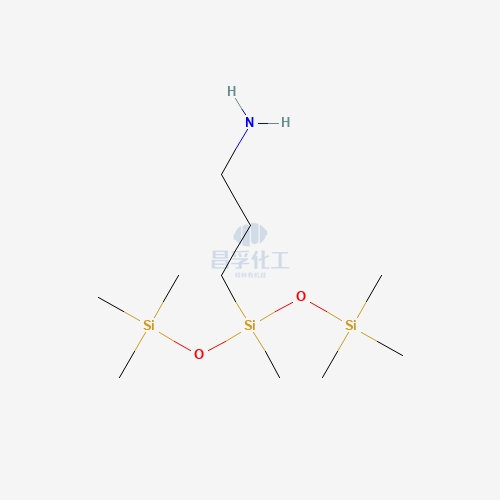

- Methyl-based silicone monomers: These are the most widely used types of silicone monomers. The methyl group (–CH₃) provides a flexible, low-cost material that is highly stable and water-repellent.

- Phenyl-based silicone monomers: These monomers are used in applications requiring high-temperature stability. The phenyl group (–C₆H₅) is less flexible than the methyl group but offers improved thermal resistance and electrical properties.

- Vinyl-based silicone monomers: Vinyl groups (–C₂H₃) can undergo polymerization or crosslinking, enabling the creation of silicone elastomers that are used in a wide range of applications, from automotive seals to medical devices.

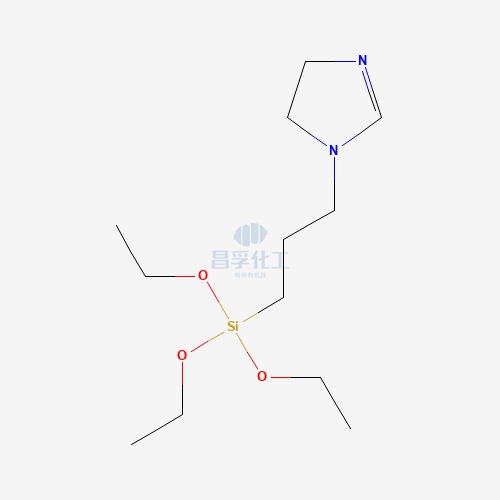

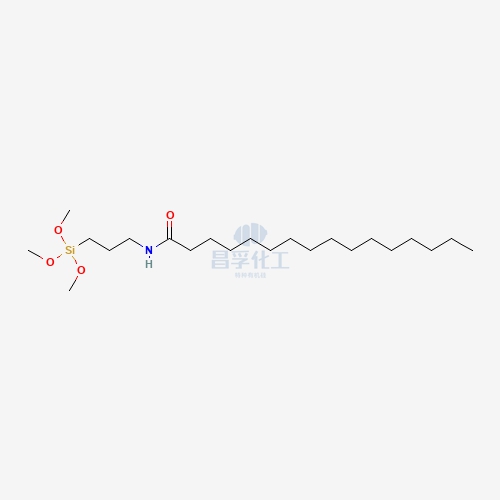

- Amino-functionalized silicone monomers: These monomers contain amino groups, which can form bonds with other materials, making them useful in adhesives and coatings.

- Fluorosilicone monomers: With the addition of fluorine atoms, these monomers create silicones with exceptional chemical resistance, making them ideal for applications in aggressive environments.

Applications of Silicone Monomers

The unique properties of silicone monomers, such as high heat resistance, flexibility, water repellency, and chemical stability, make them invaluable in a wide range of applications. Once polymerized, silicone polymers can be found in products such as medical devices, automotive components, construction materials, electronics, and consumer goods. Here are some notable applications of silicone monomers:

1. Medical Devices and Healthcare

Silicone monomers and their derivatives are widely used in medical applications due to their biocompatibility, stability, and resistance to bacteria and mold. Silicones are used in products like catheters, medical implants, prosthetics, and wound dressings. The flexibility and soft texture of silicone materials make them ideal for applications that require comfort, such as breast implants and orthodontic devices.

2. Automotive Industry

Silicone polymers derived from silicone monomers are crucial in the automotive industry, where they are used in gaskets, seals, lubricants, and coatings. These materials withstand high temperatures, oil exposure, and wear, making them essential for automotive components that operate in extreme conditions.

3. Electronics and Electrical Insulation

Silicone monomers also play an important role in electronics. Silicones are used for electrical insulation, as they offer excellent dielectric properties and resistance to extreme temperatures and environmental conditions. Silicone-based materials are used in components like connectors, capacitors, and heat shields.

4. Construction Materials

In construction, silicone-based sealants and adhesives are used for bonding and sealing applications due to their water resistance and durability. Silicone monomers form the backbone of these materials, which are employed in everything from window seals to roof coatings.

5. Cosmetics and Personal Care

In the cosmetics industry, silicones derived from silicone monomers are used in hair care products, moisturizers, and makeup. Silicones provide a smooth, non-greasy texture, improve spreadability, and enhance the appearance of products. They are also known for their ability to create a barrier against moisture, which is essential in skin and hair care.

Conclusion

Silicone monomers are the building blocks of a class of materials that have transformed multiple industries due to their unique chemical properties and versatility. From their synthesis to their application, these monomers offer insight into the incredible flexibility and utility of silicone-based materials. The ability to modify silicone monomers with different organic groups and functional groups gives rise to a wide range of polymers with customized properties for specific uses. Whether in healthcare, automotive, construction, or electronics, silicone monomers remain indispensable in creating materials that offer durability, flexibility, and resistance to extreme conditions, making them truly remarkable in the world of materials science.

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog