Contact Changfu Chemical Now!

+86 27 8439 6550 | +86 181 6277 0058

Coating Silicone: The Ultimate Guide to Applications and Benefits

Introduction

Coating silicone, a versatile material known for its exceptional properties, has become indispensable in numerous industries. From electronics to construction, silicone coatings offer unmatched benefits such as durability, flexibility, and resistance to extreme conditions. This comprehensive guide delves into the intricacies of coating silicone, exploring its applications, benefits, and the science behind its remarkable performance.

What is Coating Silicone?

Definition and Composition

Coating silicone refers to a type of silicone-based material applied as a protective layer on various surfaces. Its composition includes silicone polymers, often enhanced with additives to improve specific properties like adhesion, durability, and thermal stability.

Types of Silicone Coatings

- Silicone Elastomers: Known for their flexibility and resilience.

- Silicone Resins: Provide high thermal stability and are used in high-temperature applications.

- Silicone Gels: Often used in electronics for their excellent dielectric properties.

The Science Behind Coating Silicone

Chemical Structure

Silicone coatings are primarily composed of siloxane (Si-O-Si) chains, which contribute to their unique properties. The presence of organic groups attached to the silicon atoms allows for customization of the coating's characteristics.

Key Properties

- Thermal Stability: Silicone coatings can withstand temperatures ranging from -60°C to 300°C.

- Chemical Resistance: Resistant to oils, solvents, and chemicals, making them ideal for harsh environments.

- UV Resistance: Protects surfaces from degradation due to ultraviolet light exposure.

Applications of Coating Silicone

Electronics and Electrical Industry

- Protective Coatings for Circuit Boards: Prevents moisture and dust ingress, ensuring long-term reliability.

- Insulation in Cables and Wires: Enhances electrical insulation and flexibility.

Automotive Industry

- Engine Components: Provides heat resistance and protects against oil and chemical exposure.

- Exterior Parts: UV-resistant coatings maintain appearance and performance.

Construction Industry

- Sealants for Joints and Gaps: Offers flexibility and weather resistance.

- Roof Coatings: Provides waterproofing and thermal insulation.

Medical and Healthcare

- Medical Devices: Ensures biocompatibility and sterilization resistance.

- Prosthetics and Implants: Enhances comfort and durability.

Aerospace Industry

- Thermal Protection Systems: Withstands extreme temperatures in space environments.

- Fuel Tank Coatings: Prevents fuel leakage and degradation.

Advantages of Using Coating Silicone

Durability and Longevity

Silicone coatings provide long-lasting protection, reducing the need for frequent maintenance and replacements.

Flexibility and Elasticity

Maintains performance under mechanical stress, making them suitable for dynamic environments.

Environmental Resistance

Withstands exposure to extreme temperatures, UV light, and harsh chemicals, ensuring reliability in diverse conditions.

Enhanced Aesthetic Appeal

Maintains appearance with resistance to fading, cracking, and discoloration.

Safety and Health Benefits

Non-toxic and biocompatible, suitable for applications in healthcare and food industries.

How to Apply Coating Silicone

Surface Preparation

- Cleaning: Remove dirt, grease, and contaminants for optimal adhesion.

- Priming: Apply primers to enhance adhesion on challenging surfaces.

Application Methods

- Spraying: Ensures even coverage and is suitable for large surfaces.

- Brushing: Ideal for detailed and small-area applications.

- Dipping: Provides uniform coating for irregularly shaped objects.

Curing Process

- Room Temperature Vulcanizing (RTV): Cures at room temperature without additional heat.

- Heat Curing: Accelerates the curing process and enhances properties like hardness.

Common Issues and Solutions in Silicone Coating

Adhesion Problems

- Solution: Proper surface preparation and use of appropriate primers.

Inconsistent Coating Thickness

- Solution: Use controlled application methods and ensure even distribution.

Bubbling and Blistering

- Solution: Apply in controlled environments to avoid moisture and contaminants.

Cracking and Peeling

- Solution: Ensure flexibility and compatibility with the substrate material.

Future Trends in Silicone Coating Technology

Nanotechnology Integration

- Enhances properties like scratch resistance and thermal conductivity.

Eco-friendly Formulations

- Development of silicone coatings with reduced environmental impact.

Advanced Application Techniques

- Automation and robotics for precise and efficient application.

Multifunctional Coatings

- Combining properties like self-healing, antimicrobial, and superhydrophobic characteristics.

Case Studies: Successful Applications of Coating Silicone

Protecting Electronic Components

In a major electronics company, silicone coatings extended the lifespan of circuit boards by preventing corrosion and moisture damage, resulting in significant cost savings.

Enhancing Automotive Parts

An automotive manufacturer applied silicone coatings to engine components, improving heat resistance and reducing maintenance frequency, leading to improved vehicle performance and customer satisfaction.

Medical Device Innovation

A medical device company utilized silicone coatings for implants and prosthetics, enhancing biocompatibility and patient comfort, and receiving positive feedback from healthcare providers.

Selecting the Right Coating Silicone

Factors to Consider

- Application Environment: Consider temperature, chemical exposure, and mechanical stress.

- Surface Material: Ensure compatibility with the substrate for optimal adhesion.

- Desired Properties: Identify key requirements such as flexibility, durability, and resistance characteristics.

Consulting with Experts

Seek advice from silicone coating specialists to select the most suitable product for specific applications.

Frequently Asked Questions

What are the main benefits of using silicone coatings? Silicone coatings offer durability, flexibility, environmental resistance, and safety, making them ideal for diverse applications.

Can silicone coatings be used on all types of surfaces? While silicone coatings are versatile, it’s essential to ensure compatibility with the specific substrate and prepare the surface adequately for optimal adhesion.

How long do silicone coatings typically last? The longevity of silicone coatings depends on the application environment and maintenance. They are known for their durability, often lasting several years without significant degradation.

Are silicone coatings safe for use in medical applications? Yes, silicone coatings are biocompatible and widely used in medical devices, implants, and prosthetics due to their safety and performance.

What is the curing process for silicone coatings? Silicone coatings can cure at room temperature (RTV) or with heat curing. The chosen method depends on the desired properties and application requirements.

How do silicone coatings enhance the performance of electronic components? Silicone coatings protect electronic components from moisture, dust, and chemicals, improving reliability and extending lifespan.

Conclusion

Coating silicone stands out as a remarkable material with a broad range of applications and benefits. Its unique properties such as durability, flexibility, and environmental resistance make it indispensable in industries like electronics, automotive, construction, and healthcare. Understanding the science behind silicone coatings, their application methods, and addressing common issues ensures optimal performance and longevity. As technology advances, silicone coatings continue to evolve, offering even more innovative solutions for various challenges. Embracing silicone coatings can lead to enhanced performance, cost savings, and sustainable practices across multiple sectors.

Popular Silicon Compounds

Popular Silicon Compounds

Related News & Blog

Related News & Blog

+86 27 8439 6550

+86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

+86 27 8439 6550 | +86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

No. 666, Gaoxin Avenue

Hongshan District, Wuhan City

Copyright © Hubei ChangFu Chemical Co., Ltd. All Rights

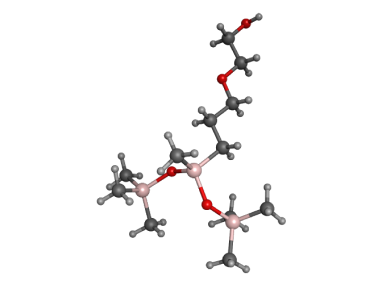

![N-[5-(Trimethoxysilylpropyl)-2-aza-1-oxopentyl]caprolactam CAS: 106996-32-1 106996 32 1 N-[5-(Trimethoxysilylpropyl)-2-aza-1-oxopentyl]caprolactam CAS: 106996-32-1 106996 32 1](https://cdn.yofishseo.com/1363882761272232/106996-32-1.jpg)